Polyurea has proven to be a long-lasting material that is widely used in industries. Its unique properties, such as its ability to protect against corrosion in settings and serve as a coating in construction, have made it a popular choice among professionals. Looking toward the future, the prospects for polyurea are promising, with advancements, expanded applications, and growing demand expected to drive its growth over the decade. This article delves into what lies for polyurea and the factors that will influence its development in the coming years.

The Changing Role of Polyurea

Polyurea has already demonstrated its value across industries due to its curing time, flexibility, and resistance to chemicals and abrasion. These qualities have made it essential for applications that require protection. As industries progress and face challenges polyurea is positioned to assume a greater role in meeting the needs of contemporary construction, manufacturing and infrastructure projects.

An area where polyurea is anticipated to expand is safeguarding infrastructure. With governments and private entities investing in enhancing and upkeeping infrastructure, there will be an increased demand for coatings that offer long-term performance.

Due to its protective properties, polyurea is a solution for protecting structures like bridges, tunnels, pipelines, and other infrastructure from corrosion, water damage, and physical harm.

In the construction industry, polyureas’ ability to create an impenetrable barrier is highly beneficial for waterproofing foundations, roofs, and floors. As building codes focus more on sustainability and energy efficiency polyureas role in forming moisture structures will become increasingly important.

The future of polyurea technology looks promising, with research aiming to enhance its performance, broaden its applications and address issues. Innovations include developing coatings with UV resistance and better adhesion to various surfaces. Incorporating nanotechnology, into polyurea coatings is another area of advancement.

Scientists aim to enhance coatings’ strength, flexibility, and durability by adding nanoparticles to the polyurea chemistry. These nano-infused coatings may provide protection while retaining the material’s flexible attributes.

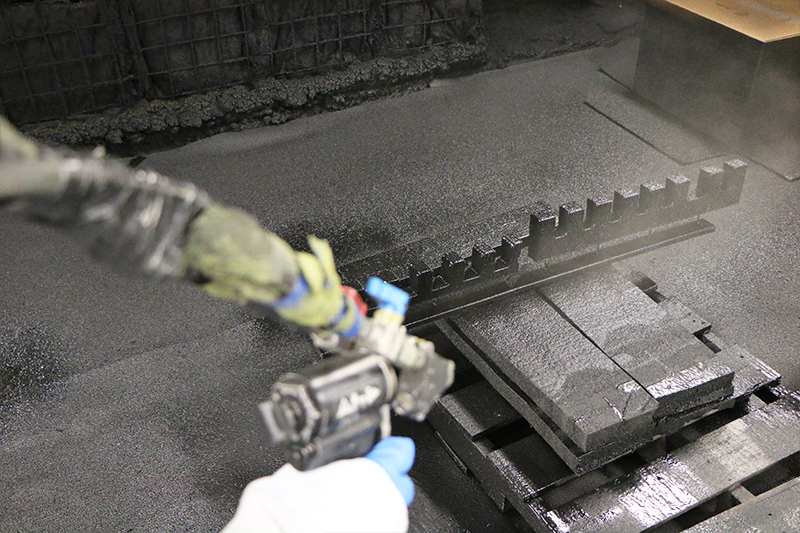

Furthermore, advancements in application techniques for polyurea are anticipated. The development of spray equipment and methods is set to enhance the efficiency and accuracy of coating applications. These improvements will simplify the process of applying polyurea coatings in large-scale projects, minimizing waste and ensuring coverage. The capability to apply polyurea under a range of conditions will increase its attractiveness as a preferred choice for endeavors in demanding climates or remote areas.

Sustainability and Environmental Impact

As global attention turns towards sustainability,, the effects of materials like polyurea will be scrutinized more closely. In response, the polyurea sector is likely to prioritize creating formulations and application techniques that reduce the carbon footprint associated with polyurea coatings.

One method to boost the sustainability of polyurea involves utilizing bio based or renewable resources in its production process. Researchers are investigating alternatives that replace petroleum-derived components with plant-based options. This shift could lessen the impact of polyurea while upholding its performance standards.

Besides developing new materials, the industry is also focusing on ways to reduce waste and enhance the recyclability of polyurea coatings. Progress in removing and recycling coatings could simplify the process of reusing or repurposing materials coated with polyurea once they reach the end of their life, thereby promoting a circular economy.

Additionally with tightening regulations on compounds (VOCs) and other emissions, the development of low VOC or VOC free polyurea formulations will play a crucial role. These formulations will help meet standards while ensuring that polyurea remains a choice for various applications.

The versatility of polyurea leads to its applications continually expanding. In the ten years we can anticipate seeing polyurea being utilized in innovative manners as industries recognize the advantages of this resilient material.

One emerging area gaining attention is employing polyurea in the energy sector. As society transitions towards energy sources there will be an increasing demand for protective coatings for wind turbines solar panels and other renewable energy structures. Polyureas resistance to elements, like UV rays, moisture and temperature changes makes it well suited for safeguarding these assets and ensuring their durability.

The automotive and aerospace industries may also explore applications, for polyurea. In the field the lightweight and impact resistant nature of polyurea makes it an appealing choice for coatings, bumpers and other parts that require both durability and weight reduction. In aerospace polyurea could be utilized to shield aircraft structures from harm, maintenance expenses and prolong the lifespan of crucial components.

With advancements in printing technology polyurea could also have a role in manufacturing. The capability to 3D print polyurea components or coatings could introduce opportunities for customized high performance parts designed for uses.

The Importance of Training and Expertise

As polyurea technology progresses, the significance of training and expertise will become increasingly critical. Effective application of polyurea necessitates professionals who comprehend the material’s characteristics, the equipment utilized, and the methods required to achieve outcomes.

In the coming years,, demand for polyurea training programs will rise as various industries embrace this material. These programs will need to keep pace with advancements in polyurea technology to ensure that applicators possess the knowledge and skills needed to apply the formulations and techniques effectively.

Industry leaders such as ArmorThane, renowned for its polyurea training programs, are set to play a role in meeting the rising demand. Through hands-on guidance, technical assistance, and continuous learning opportunities, these training initiatives will ensure that the upcoming generation of polyurea applicators can deliver the top-notch outcomes expected by the industry.

In Summary

The future looks promising for polyurea in the coming decade driven by advancements broadening applications and a focus on sustainability. As various sectors increasingly acknowledge the benefits of polyureas strength, flexibility and quick curing properties its significance in construction, infrastructure development, automotive industry and other fields is poised to grow. With advancements and a dedication to training and expertise polyurea is well equipped to tackle challenges and maintain its relevance as a crucial material, in an ever evolving world.