Advanced adaptable polyurea coatings, used directly to the substrate or pre-applied to geotextile liners, offer smooth containment for facilities as well as field applications.

When made use of for primary or secondary containment, traditional coatings have actually been too inflexible and not completely flexible to suit ground, concrete or steel substrate activity. This shortage can bring about splits or holes creating in both the substrate and the coatings, which can endanger containment.

Nonetheless, the solution of tough, monolithic, adaptable coatings such as polyurea are now resolving this problem for professionals, designers, and also facility managers. When applied straight to concrete or steel surface areas, polyurea not just enhances as well as protects the underlying substrate yet can also link voids or splits of 1/8″ or larger.

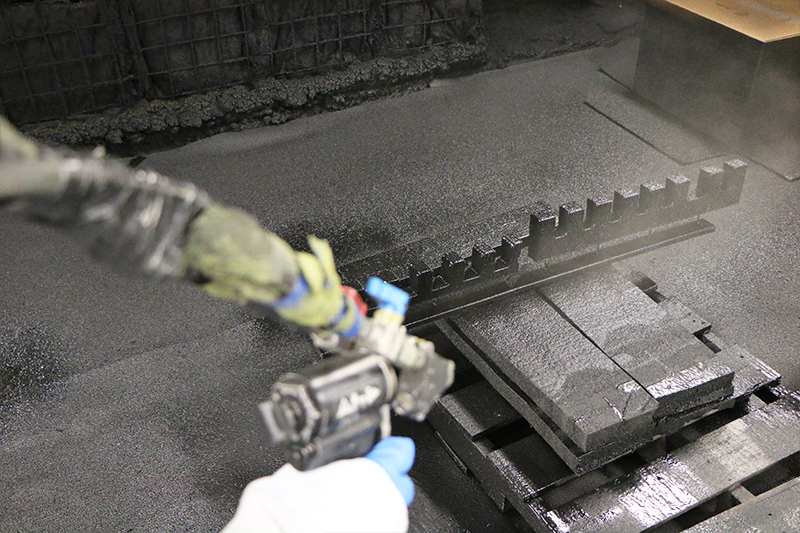

Furthermore, polyurea is currently being pre-applied to geotextile linings that can be rapidly rolled out in sheets to shield extra heavily broken surfaces or for usage in area applications such as dust or crushed rock pads at piercing websites. When installed, applicators need just layer the seams of the liners to produce a monolithic surface that is ideal for containment.

Containment Requirements

Whether at refineries, industrial plants, or various other manufacturing facilities, government and state policies mandate using primary as well as secondary containment systems to maintain harmful or unsafe compounds from leaving into the ground as well as possibly getting in the supply of water.

Suggested in this need is the understanding that primary containment (typically by means of a concrete or steel storage space vessel that holds chemicals or liquids) is not foolproof. Though resilient, metals rust, concrete splits and is porous too, so will certainly seep fluids if uncoated. This calls for secondary containment, which usually takes the kind of concrete pits with barriers mounted around the boundary of a storage tank or other storage container.

To safeguard these frameworks, coatings such as epoxies, tars, as well as polyurethanes are commonly used as an extra barrier of protection. Nonetheless, these standard coatings are regularly stringent when healed as well as can crack along with the concrete.

Normal coatings do not hold up well to substrate motion or daily, seasonal, or process-related thermal expansion and contraction, which can lead to splits and also leaks,” states Chad Faught, sales representative for ArmorThane, a leading producer of polyurea chemical and polyurea machinery.

When put on substrates such as concrete or steel, the spray-applied waterproof coating produces a durable, seamless, flexible, protective barrier that stops leaks and strengthens the stability of primary as well as secondary containment systems. The coating exhibits remarkable physical residential properties such as solidity, tensile strength, as well as crack linking and also prolongation approximately 400%, to develop a durable, industrial-grade protective lining.

” Polyurea can link splits along with flex at a rate similar to concrete as well as steel,” says Faught. “This not only helps it last but likewise seals the concrete so it does not soak up impurities if there is a spill inside the included location.”

When compared to traditional coatings, Faught also appreciates the quick go back to service feasible when splashing the polyurea system for containment.

While traditional coatings such as cementitious, epoxies, tars, as well as polyurethanes will prematurely fall short otherwise installed under a fairly slim series of temperature levels, polyurea is designed for setup and usage from -40 ° F to +350 ° F. It establishes and also cures quickly as well as will hold up against decades of freeze-thaw biking, as well as large variants of temperature and humidity.” After spraying the polyurea, go back to service is virtually instantaneous, which can make a big distinction in reducing production downtime,” claims Faught. “We covered concerning 8,000 sq. ft. of concrete in 12 truck-offloading areas that called for drive-in containment with our polyurea. Within minutes of spray application, trucks were securely driving across it.”

Fast, Reliable Containment in the Field

Although splashing polyurea straight to the substrate has lots of advantages, for containment over soil, crushed rock, or perhaps concrete that is also damaged to be successfully fixed up, pre-sprayed composite panels provide remarkable protection.

This service is specifically suited to field applications that should have the ability to endure rush hour from trucks filling or dumping products. Although plastic linings that are seam-welded together are frequently made use of for such applications, they are extra quickly penetrated as well as can bunch up under hefty usage.

” For primary containment at oil area piercing sites, we used to put different plastic systems on the well pads, however we relocated far from that because plastic was not long lasting enough,” says Faught.

Repairing plastic liners additionally provides an issue at the seams, when harmed locations are eliminated and new areas welded in, claims Faught. “The outcome is a patchwork liner with seams that are prone to failure due to incorrect welding as well,” he states.

As a remedy, Faughtresorted to geotextiles with pre-applied polyurea for its substantial benefits in sturdiness as well as reusability.

Polyurea items are a lot more durable than plastics for containment systems,” says Faught. “When required, we can customized use even more polyurea millage to geotextile panels and also berms to suit also the heaviest truck usage and lorry abuse.”

To validate the strength of the polyurea coating on containment floor coverings and also berms, as a matter of fact, Faught conducted a number of examinations.

” I ran an 11,000 extra pound skid loader onto a containment mat, stood the forks directly as well as attempted to pierce it– but it did not penetrate through,” says Faught.. “We also ran 6,044 completely packed water trucks across a containment system and it withstood it with absolutely no holes as well as no compromise to the liner.”

Faught credits both the sturdiness of the ArmorThane polyurea along with its extensive recoating home window for the capacity of his firm to thoroughly reuse its containment systems.

” To recycle a containment system, we’ll suffice up right into rolls, roll it up and move it. Then we’ll take it back out, respray certain locations, as well as re-install the original containment system at one more area,” clarifies Faught.

To produce one of the most long-lasting, seamless, as well as recyclable containment floor coverings as well as berms, Faught looked to determine the very best polyurea for the application.

“Some polyureas look great the first time you spray it, yet the preparation required to get any kind of seams to bond for reuse can be challenging,” states Faught. Nevertheless, we have actually located the prolonged open home window for recoat and also repair work of the polyurea allows us to quickly remove any type of harmed area of geotextile, placed a new item in, as well as spray the seams to make it essentially seamless once again. We get better repair work and even more reuse out of our containment systems.”

Stands up to Extreme Climate

While typical coatings such as cementitious materials, epoxies, and polyurethanes will prematurely stop working otherwise mounted under a relatively slim range of temperature levels, polyurea is created for setup as well as usage from -40 ° F to +350 ° F. It will certainly endure years of freeze-thaw biking, as well as wide variants of temperature level as well as humidity.

” When you’re above ground in the Midwest, you have freeze and thaw with concrete growth, contraction, as well as breaking,” states Garry Froese, President of ArmorThane USA Inc. “We needed a lining that would certainly relocate with the framework with the various seasons as well as tank temperature level differentials. For that, polyurea works quite possibly.”

To endure extreme weather conditions at a Missouri wastewater treatment plant, Froese chose polyurea for a secondary containment area around ferric chloride tanks. “After filling in fractures with cement as well as restoring the concrete, we splashed the polyurea on geotextile to offer a really nice containment area for the ferric chloride storage tanks,” he says.

Froese, whose firm does a huge amount of wastewater-related deal with containment, clarifiers, containers, and damp wells, states that the polyurea has an added advantage in reducing constant clarifier maintenance. “Normally clarifier upkeep crews require to utilize high-pressure power washers for hours to clean solid waste from concrete surface areas,” states Froese. Given that the polyurea gives waterproofing as well as has a cleanable surface area, crews can simply hose down the clarifier to clean it. This can cut required once a week clarifier cleansing by two-thirds.”

For wastewater-related recovery, polyurea is a premium coating for any application that requires split bridging, durability, chemical and also temperature resistance, as well as a rapid turnaround,” concludes Froese.