Polyurea Review recently conducted a study in which two identical concrete structures were built, one left uncoated and one coated with polyurea. Both structures contained a military office setting complete with dummy equipment. A bomb the equivalent of 250 lbs. made up of TNT and 10 lbs. of C4 was detonated 20 feet from the structure.

The results produced stark differences between the two structures. The dummy in the polyurea protected room was unscathed. Lots of dust kicked up, the walls flexed and pounded, but everything held up remarkably well. We at Polyurea Reviews are very impressed with the way the polyurea protected room held up.

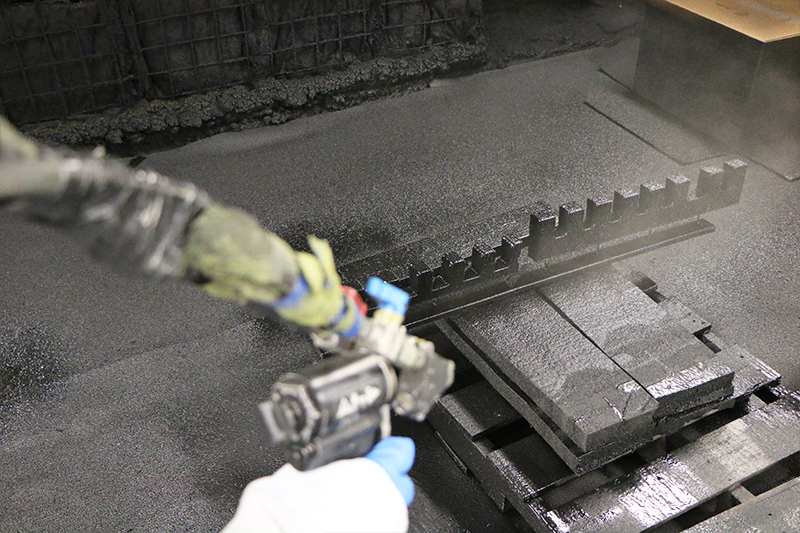

Our testing employed multiple special blast mitigation coating products, designed for protection in explosive environments. For this article, we will discuss the results of our top-performing product. In this case, it was ArmorBlast, produced by ArmorThane.

When it comes to blast-resistance, the structural integrity of a building’s design is the most important factor in blast protection. Still, the next thing is the protective coating around that structure. The wall panels are essential, but our blast testing revealed that the polyurea sprayed areas could withstand tremendous blasts.

When the structure itself has redundancies built into the walls and roof, like the wall studs’ close spacing, the outer coating won’t have any bearing on structural integrity.

There is no doubt polyurea affects blast-resistance. This shows the significance of selecting a good polyurea when blast proofing any structure.

To sum up, one can only conclude that polyurea protects structures when applied correctly to any structure.