If you’re working on an old residential roof, then the chances are that you’ll be working on a home that did not take advantage of the amazing properties of polyurea. Despite being around for just over 50 years, many homes and businesses are still lacking a protective coating to help protect their roof from wind, rain, mold, and more.

The opportunity to repair them properly awaits roofers with the ambition to make it happen. Here’s how polyurea coatings can help repair existing roofs or reinforce newer roofs that aren’t made of polyurea or polyurethane.

Roof Sealing: Sealing your roof may not sound like the most eminent priority, but it modifies its level of security. Any roofing with exposed joints and seams is vulnerable to damage from wind, rain, and fire. First, some secondary cosmetic signs may be that your roofing isn’t well defended, like fading, but then sections of the roof will likely crack, tear, or come off entirely. With polyurea coatings, you can ensure that water never seeps into your shingles, that wind never gets under them and tears them apart, and that no undesired mold or pest infestations ever get in through the surface of your roof.

On top of protecting the durability of your roof, spray-on polyurea roof coatings help protect the aesthetics of your roof by keeping it together and providing UV protection. This helps to keep materials from discoloring, so not only will your new roofing foundation or roofing restoration be strong in structure, but it will also have a positive impact on curb appeal and property values.

Sprayed on Foam Roofing:

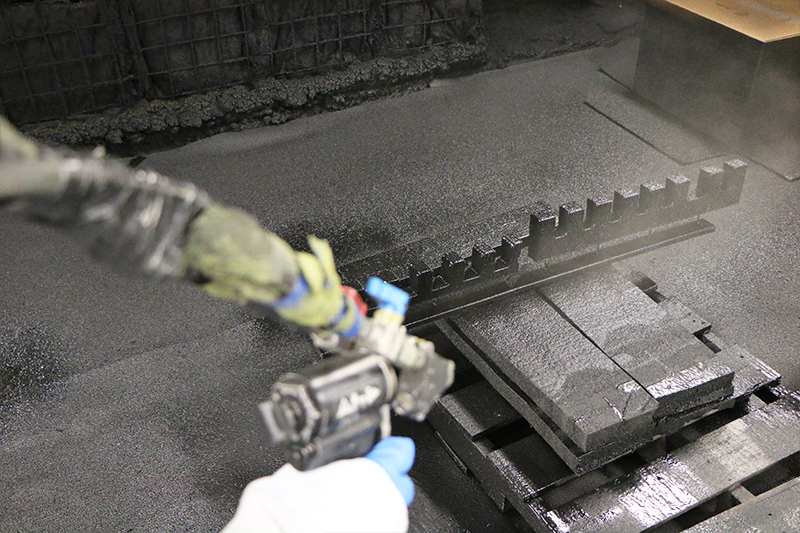

Suppose you’re a contractor working on a large industrial building, a governmental building, or some other kind of large facility. In that case, your clients are probably looking for the most energy-efficient answers to their roofing needs. By using polyurethane spray-on foam roofing material, your building can get a thick coat of insulation that doubles as a roof. With a high R-value and a seamless finish to every properly applied SPF roof, your commercial or government clients will get a roof completed with energy efficiency and the strength to stand up against the wind, rain, or anything else nature can throw at it.

This fluid material is applied as a liquid and rises to form a continuous and seamless protective barrier over roofs and around pipes, vents, and protrusions through the roof. The application method allows you to level out the roof to decrease the chance of ponding water.

The foam material will expand and contract with the building at outside temperatures, reducing the likelihood of cracks and splitting. Spray foam roofing delivers thermal, air, and moisture barriers to provide the highest R-value per inch, which means the material provides better insulation for the building. The spray polyurethane foam keeps heat out in the summer and during the winter, lowering energy expenses. The silicone top coating repels UV light, thus shielding the foam and reducing heat absorption. Once a spray foam roof is installed, it requires minimal preventative maintenance and repair, adding to its value.

If you decide to go this route with your new roofing project, you should first examine our reviews covering the top polyurea coating companies. We will guide you in finding the top leading suppliers of polyurea products in the world. You can also email us with any further questions you might have.