Cities rely on a lot of infrastructure that they rarely see. Beneath roads and sidewalks, manholes provide access to sewer systems that move waste and stormwater away from homes. These structures must hold up against years of chemical exposure, groundwater pressure, and shifting soil. When they fail, the effects rise to the surface. Sinkholes form, streets crack, and systems back up. To prevent these outcomes, cities line manholes with protective coatings.

Protective Coatings For Manhole Lining

Manhole linings shield the concrete or brick walls from corrosion. Wastewater contains gases that eat away at unprotected surfaces. Over time, hydrogen sulfide gas turns into sulfuric acid. That acid breaks down the internal structure of manhole walls. Moisture enters, cracks spread and roots follow. In some cases, full collapse occurs.

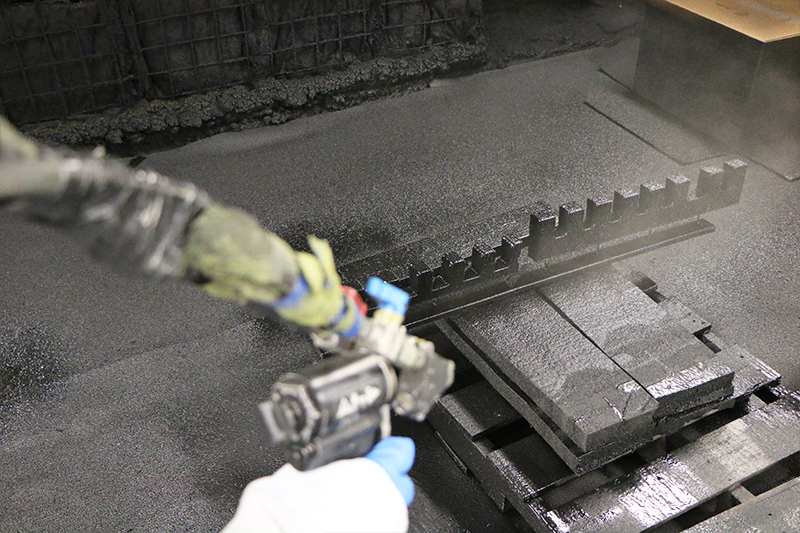

To avoid these problems, engineers apply coatings that stop water, gas, and soil from breaking through. One of the most effective materials for this job is polyurea. Unlike older materials, polyurea cures fast and bonds tightly. It resists both chemical attack and physical wear. Once sprayed inside a cleaned and prepared manhole, the coating forms a seamless barrier. It conforms to every surface and locks in place.

Why Polyurea For The Ultimate Protection?

Polyurea does more than seal. It extends the life of aging infrastructure. Many sewer systems date back decades. Their manholes were not built to resist today’s chemical loads or water flows. Instead of replacing them, cities rehabilitate them. They strip away loose material, patch the surface, and spray polyurea to restore integrity.

Crews can finish a manhole lining in a single day. This limits disruption in neighborhoods. It also reduces labor costs. Because polyurea sets within seconds, workers do not need to wait between steps. They move from cleaning to spraying to backfilling with minimal delay.

Proper Surface Prep Makes Or Breaks A Coating

Teams remove grease, roots, and deteriorated material. They may use water blasting or mechanical grinding to reach clean substrate. Only then does the spray rig come out. The crew mixes polyurea at high pressure. It exits the spray gun as a heated stream and bonds instantly with the manhole wall.

Enter Polyurea Spray Rigs

Not every city contracts this work; some municipalities spray their own manholes. With training and equipment, local crews can take over projects once given to outside contractors. The approach makes sense for cities with many manholes and long-term repair plans. It also keeps budgets under local control.

That shift has led to more cities investing in polyurea spray rigs. These rigs carry the heaters, proportioners, and guns needed to apply coatings with precision. Crews store them in trailers or trucks and deploy them across the city. With each rig, cities gain more control over scheduling and repairs.

Not All Manholes Are The Same

Still, not all manholes need the same solution. Some suffer from inflow and infiltration. Groundwater enters through cracks and joints. Other structures face chemical corrosion. Some show signs of collapse. Engineers evaluate each site before choosing a repair. In many cases, polyurea meets the conditions best.

The Advantage Lies In The Chemistry

Polyurea forms from the reaction of an isocyanate with an amine resin. That reaction happens fast. It produces a tough, flexible coating that tolerates movement, heat, and chemical stress. Because of its strength, polyurea works not just for sealing but also for structural reinforcement.

Manhole rehabilitation becomes part of a broader system upgrade. When cities reline pipes, rebuild pump stations, or improve drainage, they often include manholes in the project. Overlooking them can lead to premature failure of nearby components. Water finds the weakest link and polyurea helps remove that vulnerability.

Weighing Your Options

Choosing the right coating means weighing lifespan, cost, and application time. Polyurea does not rank as the cheapest option upfront. But its performance reduces long-term maintenance. Cities that use it tend to recoat less often. They avoid excavation and prevent emergency repairs.

Crews who work with polyurea must receive proper training. They must understand how to prepare surfaces, control temperature, and monitor spray ratios. Mistakes during application can cause peeling or voids. When applied correctly, the coating adheres without fail. It bridges gaps, fills voids, and stops leaks before they start.

Environmental Benefits

For cities considering in-house work, manhole rehabilitation with polyurea makes logistical sense. It also offers environmental benefits. Sealed manholes reduce the amount of stormwater entering sewer systems. That lowers the risk of overflow events. It also keeps treatment costs down.

It’s What You Don’t See That Matters

At the street level, no one notices a lined manhole. But below ground, the difference matters. Infrastructure lasts longer. Streets stay intact. Budgets stretch further. And water stays where it belongs.

The Future Of Polyurea For Manhole Lining

Polyurea will continue to play a role as cities plan future upgrades. Its properties—fast set time, high chemical resistance, long lifespan—match the challenges of aging sewer systems. As new research improves formulas and application methods, the material will likely remain a first choice for lining manholes.

Whether done by contractors or in-house teams, manhole lining protects more than just a hole in the ground. It preserves the systems that support daily life. It helps cities stay ahead of decay. And with polyurea, it does so with strength and speed few materials can match.