The stability of water and wastewater infrastructure is at risk due to corrosive conditions as well as extreme weather conditions and mechanical pressure. These facilities remain safe and efficient to operate through proper maintenance standards. Sherwin-Williams gave recognition to the best water and wastewater projects of 2024 through its Impact Awards program which showcases the importance of advanced coatings in protecting critical infrastructure.

Celebrating Industry Leaders

For this year’s top project, North Dakota’s Fargo Regional Water Reclamation Facility. The facility went through a $124 million expansion of its treatment capacity to more than 100 million gallons per day through a recent renovation process. Due to increasing demand and the need for long-term durability, the project implemented high-performance coatings to prevent corrosion and increase the lifespan of major components. The protective coatings application work at the facility structures was done by Protech Contracting Services Inc. which operated as the designated applicator while PKG Contracting Inc. led the entire project initiative.

Boosting water treatment plant productivity while ending pollution discharges at the Daytona Beach Ralph Brennan Water Treatment Plant in Florida stood second in the competition. The project demanded the removal of old coatings from six deteriorating basins, followed by structural repairs and the application of new protective layers. Experiences with Exceletech Coating and Applications LLC and PC Construction achieved success in enhancing these critical systems without interruption while servicing the city’s 70,000 residents. Protective coatings of specific selection and precise application helped the plant enhance its efficiency as it continues to operate through future years.

Why Protective Coatings Matter in Water and Wastewater Treatment

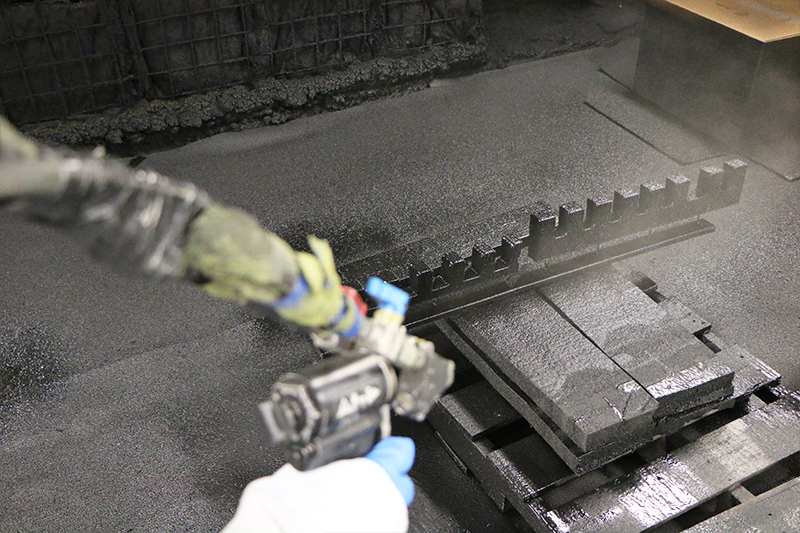

Water treatment plants operate in aggressive environments. The combination of moisture, chemicals, and temperature fluctuations causes material to break down. Protective systems must be applied to concrete surfaces and steel reinforcements and containment structures, among others, to prevent failures that could threaten public health and environmental safety. Modern coating technologies provide long-term infrastructure solutions which also lower maintenance expenses. Water treatment facilities benefit significantly from polyurea and epoxy coatings, along with polyurethane coatings against corrosion and both abrasion and leakage. The evaluated materials form fully impermeable barriers that endure water seepage and chemical damage for tanks, basins, and pipelines.

The Role of Polyurea in Water Infrastructureůl Among protective coatings, polyurea has gained recognition for its superior performance in water and wastewater environments. Traditional coatings do not compare to polyurea since this coating creates an instant bond with surfaces to produce a long-lasting, watertight layer which stays intact against cracking or peeling. The rapid curing capability of contractors enables them to finish their assignments quickly so that they keep critical infrastructure operational during minimal downtime. As waterproofing materials where flexibility along with high impact resistance and long durability are necessary polyurea coatings show exceptional performance. The service enables long-lasting protection against damage from thermal expansion and contraction since it covers all seasonal temperature fluctuations. The facility facilities operate under aggressive wastewater conditions, making polyurea’s chemical resistance especially valuable.

The Future of Water Infrastructure Protection

The reliability of infrastructure systems needs to increase to meet escalating water consumption standards. Protective coatings exist on the cusp of improvements that will produce better performance and sustainable characteristics. Future water and wastewater facility maintenance will depend on improved polyurea formulations, hybrid coating technologies, and environmentally safe solutions for sustainable practices. Acknowledging top-performing projects that establish new benchmarks for durability and efficiency shows coatings’ critical role in protecting infrastructure. Through protective coating innovations such as those seen in Fargo and Daytona Beach, facilities capable of operation with extended lifespans become possible.