Polyurea and polyurethane are commonly utilized in coatings; however, their characteristics and effectiveness differ based on the intended use. Even though both substances provide durability and flexibility, their unique qualities make them more appropriate for applications. Recognizing these variations is crucial for selecting the material for a project—be it industrial purposes or tasks like waterproof coating or surface preservation.

Both polyurethane and polyurea share a trait as elastomers known for their flexibility and durability against wear and tear but differ in their chemical composition. When you mix isocyanate with a resin mix high in amine groups, you get polyurethane, which hardens quickly (within seconds). But when you mix isocyanate with polyol, you get polyurethane, which hardens at different rates depending on the formulation used. The slower healing procedure provides some benefits and restricts the settings in which polyurethane can be used efficiently.

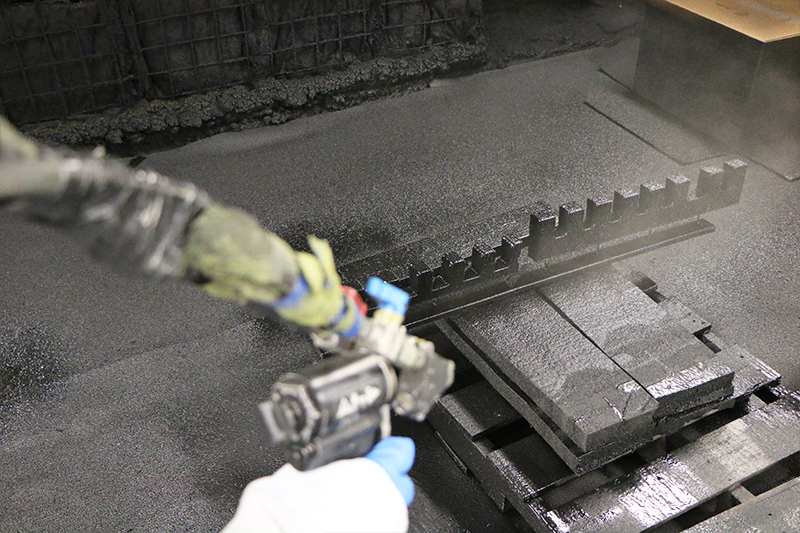

Polyurethane has an advantage due to its quick drying time, which is beneficial when time is of the essence for project completion or resumption of operations in a short period, like in industrial settings where equipment downtime must be minimized for efficiency, with the swift coating process as it sets rapidly allowing quicker progress. Polyurethane takes longer to dry than materials; it may not be suitable for projects, with tight deadlines, but it can be advantageous when a precise curing process is required.

Polyurethane is durable in its own right, but polyurea often outperforms its longevity and resilience due to the seamless and flexible membranes they create. This membrane can effortlessly withstand abrasions and harsh chemicals while effectively absorbing impacts, making it a top choice for surfaces that endure heavy usage or tough environments requiring durability and flexibility. When applying coatings on surfaces that undergo temperature fluctuations, polyurethane’s flexibility enables it to adjust alongside the surface, while polyurethane might develop cracks or brittleness as time passes.

One significant contrast between the two materials is their ability to withstand conditions.A key point is that while polyurethane is resistant to moisture and weather changes like polyurethane can provide durability against conditions such as UV radiation and dampness for applications like rooftop parking structures and marine settings. Polyurethane may not fare effectively when subjected to continuous ultraviolet exposure as compared to polyurethane, which remains durable over extended periods in outdoor settings. Over time and with sunlight exposure, polyurethane coatings may turn yellow or deteriorate, making them less ideal for applications unless supplemented with UV stabilizing additives.

In terms of how adaptable they are for different uses, polyurethane and polyurea possess their advantages; however, polyurea may offer a higher level of flexibility. Polyurea can can can be used in various temperatures and settings such as extreme cold or high humidity conditions and still maintain its performance. Polyurethane, on the other hand, necessitates more specific environmental conditions during application, and any deviations from these conditions can impact its curing process.For projects that demand coatings to be applied in surroundings, polyureatypically yields more reliable outcomes.

However, polyurethane possesses its own set of benefits.The extended curing time it offers can prove advantageous in scenarios that demand management of the coating. Polyurethane coatings can also be tailored to provide an cushier finish making them suitable for applications prioritizing comfort or sound reduction,such as in flooring or furniture.In addition polyurethane is frequently a budget option, for endeavors that do not mandate extensive levels of flexibility and endurance.

When it comes to resisting chemical effects, both polyurethane and polyurethane offer protection; however, polyurethane tends to perform better in places where the coating is constantly exposed to strong chemicals. For instance in settings where machinery faces frequent spills or chemical contact polyurethane coatings can offer durable protection. Although polyurethane is resistant to chemicals it may not provide as strong of a shield, in challenging conditions.

Both polyureas and polyurethanes serve purposes in the realm of protective coatings; however selecting one over the other is contingent on the particular needs of the project at hand.. Polyureas have swift cure time and a durable yet flexible nature, making them ideal for endeavors that necessitate the speedy application and lasting safeguard they provide. On the hand, polyurethanes offer a controlled curing process and a softer appearance making them a preferred choice, for tasks that demand a more customized solution..