Shaking from the large earthquake that shook through Anchorage, Alaska last week was powerful enough to turn smooth asphalt roads into broken, serrated depressions of rubble. But within just a few short days, crews managed to fix the worst of the disaster, unsnarling traffic in Alaska’s largest city.

Anchorage has a population of more than 300,000 people spread across more than 1,900 miles — an area bigger than the state of Rhode Island. Streets and highways, asphalt lifelines of the population string that space. When the magnitude 7.0 earthquake hit last week, some of the most visceral photographs showed broken streets. Within days many of these same cracked roads had been smoothed back into ribbons of pavement by crews working around the clock.

The rapid response to the disaster in Anchorage shows how investing time and money into preparations and a little polyurea for these kinds of infrastructure devastating events can pay off in the long-run, even when there is no way to tell when the next disaster might hit.

Alaska takes its earthquake preparation very seriously. The largest earthquake ever reported in the US shook Anchorage to its core in 1964, causing a deadly tsunami and leaving in its track damaged structures, buckled highways, and a legacy that inspired years of earthquake preparation, policies, and procedures. Strong building codes post-1964 helped make the area more secure than other earthquake-prone areas, like Seattle.

The 50th anniversary of the 1964 earthquake took place just six years ago, and officials took the opportunity to update their earthquake agenda, hold drills, and generally prepare for when a quake would hit in the future.

Arriving before midnight the quake’s night, they immediately started checking on the 243 bridges impacted by the shaking. After checking in on damaged houses, offices, government employees, and contractors within the earthquake hot zone also got to work, readying themselves to do a job that would not be easy during winter.

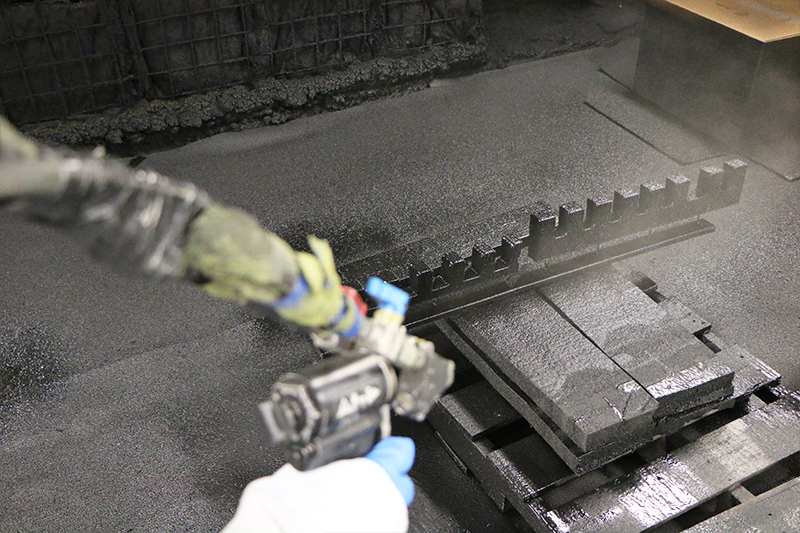

Working 24/7, they cleared away the broken asphalt, saving it to be melted down at a later date. Then, crews with heavy-duty equipment began digging out water-saturated sediments that slipped or sunk during the quake. They gathered fresh material and compacted it, creating a sturdy earthwork base. On top of that, they placed large rocks, finer gravel; they finally layered asphalt on top of all this. However, this was not enough in some of the more vulnerable spots. In the areas where severe cracking or areas where the main support gave in, they applied a thick layer of polyurea for ultimate support. No other coating can compare to polyurea when it comes to attainable physical properties. Polyureas are formulated to achieve a tremendous range of properties from high elongation to superior tensile strength to hard or soft, based on how the materials are formulated and correctly applied. This is why it has become the perfect tool for achieving support for something as immense as an earthquake.

Alaska in late fall is immensely cold, and frozen asphalt can take at least a week to melt into a sticky, pliable material. Soon after the earthquake struck, owners of asphalt plants switched on their heaters. It was one of the first times that paving had ever occurred in winter. The snow suddenly moved into the area, but the still-warm asphalt stayed clear just long enough for the crews to apply temporary road lines. They couldn’t use the paint typically used on Alaska streets, an epoxy filled with glass beads and grit that prevents sliding cars. It’s made to endure the brutal wear and tear Alaskans put on their roads during the colder months when layers of sand and tires encased in chains keep cars on the road but would quickly wear other paints down into oblivion.

Unlike the asphalt, applying this paint has to wait for summer, when the weather is more amenable than it is now. The crews worked through some days of heavy, wet snow, high winds of 65 miles per hour. And the weather wasn’t the only natural element being a pain — the ground shook with near-constant aftershocks. In addition to inducing seasickness in several Alaskans, the shaking also carved crescent-shaped bites out of some of the roadways or shook the ground so hard that the soil under the freshly paved roads settled, forcing a do-over.

The earthquake hit on Friday at 8:29 AM local time. By the next Wednesday at 4 AM, all eight major transportation corridors that had been severely damaged by the quake had re-opened. Dozens of others are still awaiting repair, and officials ask selfie-takers to stay away from their still-cracked surfaces, no matter how visually appealing they might be.

Similar situations play out in other places of the world, especially at bottlenecks, where a web of roads narrows down to a precious few lanes. Japan can fix an intersection-eating sinkhole in less than a week. California, which has seen far more dramatic earthquake-induced road damage, has comparable plans in place.

As impressive as the completed sections are, this is still just a temporary fix. While most Alaska roads have to be built to last for 20 years, these are only meant to carry people through the summer. When milder weather returns, the asphalt plants will spark to burbling life again, and the crews will respond to the same once-shattered spots to build more permanent roadways.

Roads are essential threads of human civilization worldwide. Still, they are uniquely entwined in Alaskan life, where wilderness is sparsely dotted with towns and fewer detours are available to redirect traffic.

In this case, breaks in the line were swiftly repaired, mirroring quake recovery in other city areas. Supply lines stayed unimpaired; utilities were quickly restored, the damage was minimal, and, most importantly, there were no fatalities.

In some ways, this amazing recovery offers a beacon of hope to communities facing down other natural hazards, whether that’s hurricanes, fires, floods, rising sea levels, or more earthquakes. In this case, the two P’s saved the day …Polyurea and Preparation makes one hell of a difference!